Choosing the right abrasive for processing wooden boards

Wood is indispensable for the construction industry. With regard to sustainability and the CO2 footprint of buildings, new construction methods and innovative options for the use of wood have quickly developed. In addition to these properties, wood is a regenerative material for sustainable deforestation and forest management. In addition to the above Properties is the versatility of the processing options of wood, a skin criterion for use in the construction industry. Ranging from boards to profiled wood to beams and entire floors can be made of wood. Wood is also processed into thermal and acoustic tiles and insulators.

CUMI AWUKO Abrasives GmbH

All wooden panels? The differences between MDF, MDP, OSB and plywood

For the manufacture of furniture, wall coverings, ceilings and even floors, the use of wood is an economical and functional option for the construction and expansion of buildings. The wood and panel market produce many different products depending on the manufacturing process. Depending on the manufacturing process and materials, the market differentiates between fiber, particle, fragment or entire solid wood panels. Depending on the material, the panels have properties that enable specific uses.

A selection of species can be found here and are explained in properties and main uses:

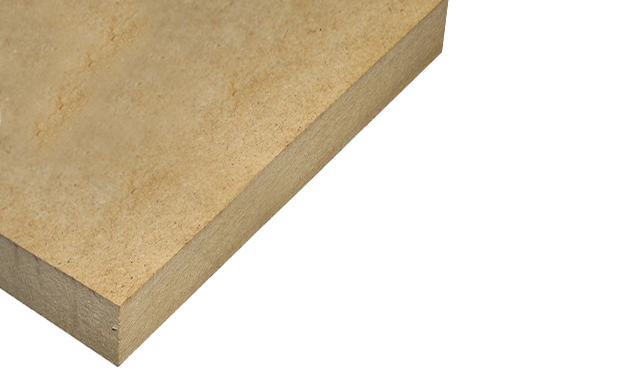

MDF (medium density fiberboard)

MDF panels consist of wood fibers that are glued with synthetic resin. The production takes place under high pressure and heat. This process enables the production of a firm and very even plate, with a smooth surface and high durability. Because the plate fibers are randomly aligned, machines can cut the plates in any direction. Untreated MDF boards, i.e. medium-density fiberboard, swell up quickly when they come into direct contact with water and thus lose their resistance to weathering. Special treatments of the MDF fiberboard provide protection against moisture and sometimes even against fire.

MDF boards are currently the most frequently used material for joinery, as they can be painted quickly and easily or glued with melamines or veneer with pattern printing. MDF boards in refined form are often used for wall and door cladding.

HDF (High Density Fiberboard)

The HDF (High Density Fiberboard) is very similar to the MDF, although the manufacturing processes are fundamentally different. These plates are pressed under higher pressure, are therefore more resistant and can carry more weight and can therefore be used for larger areas.

Chipboard and MDP (Medium Density Particleboard)

Chipboard

Chipboard is made by gluing (with resin and glue) and pressing wood waste, such as sawdust and wood chips. Chipboard is very inexpensive to manufacture, but cannot be painted because of the uneven surface. The uses of chipboard are often similar to those of MDF.

The resulting panels are widely used in the production of simple furniture.

Plywood

Plywood panels consist of overlapping wooden panels, each glued at a 90 degree angle to each other and then hot pressed. As with cross laminated timber (CLT), the cross fibers of the plywood enable the panel to withstand high loads. The use of plywood can be found in furniture manufacture, as well as in the creation of floors, ceilings, doors and worktops. Plywood panels can be painted and glued with melamine.

OSB (Oriented Strand Board)

OSB panels have a very characteristic appearance and are enjoying increasing attention in architectural design. The panels consist of wood chips, which are pressed in layers and glued with resin. They are pressed and shaped under high pressure and high temperature. They have good mechanical strength and rigidity. In addition to their good sound insulation, they have no voids and cracks in the structure. They are ecological and very durable to manufacture. OSB panels resist weather, such as rain, moisture, wind and heat. In addition, the panels are fully recyclable. However, since they have a rough surface, it is impossible to apply laminated products to them.

The main applications of OSB can be found in wall and ceiling construction, the construction of base plinths, wooden floors and cladding and furniture structures.